Scientific Cutting Tools offers a wide range of high-quality cutting tools and accessories designed for precision cutting instruments, industrial cutting equipment, and high-performance cutting tools in various industries. With a solid reputation for reliability and exceptional performance, Scientific Cutting Tools is a leading manufacturer in the field.

Their cutting-edge products are crafted from durable materials like heat-treated steel, ensuring longevity and exceptional results. These precision tools are designed to meet the demanding needs of industries such as aerospace, medical, defense, and job shop applications.

Key Takeaways:

- Scientific Cutting Tools offers a wide range of high-quality cutting tools and accessories.

- Their products are made from durable materials, ensuring longevity and exceptional results.

- They cater to various industries, including aerospace, medical, defense, and job shop applications.

- Scientific Cutting Tools is known for their reliability and exceptional performance.

- They are a leading manufacturer in the field of precision cutting instruments and industrial cutting equipment.

Coolant Ring Technology (CRT) Holders

One of the notable offerings from Scientific Cutting Tools is their Coolant Ring Technology (CRT) holders. These high-quality holders are made from heat-treated steel and feature a black oxide coating. The coolant ring technology helps reduce cutting edge temperatures, ensuring optimal performance and extended tool life. These holders are designed to improve coolant penetration, resulting in efficient and precise cutting operations.

| Features | Benefits |

|---|---|

| Heat-treated steel | Durable and long-lasting |

| Black oxide coating | Enhanced wear resistance |

| Coolant ring technology | Reduced cutting edge temperatures |

| Improved coolant penetration | Efficient and precise cutting operations |

Scientific Cutting Tools’ CRT holders are built to withstand demanding machining applications, providing reliability and consistent performance. The heat-treated steel construction ensures durability, while the black oxide coating offers excellent wear resistance. With the integration of coolant ring technology, these holders deliver optimal cooling, allowing for high-quality cuts and extended tool life.

Whether you’re working with tough materials or require precise cuts, Scientific Cutting Tools’ CRT holders are a reliable choice. Their commitment to innovative cutting solutions and use of cutting-edge technology make them a trusted partner in the industry.

Coolant-Through Thread Mills

Scientific Cutting Tools offers a range of advanced cutting tools, and their coolant-through thread mills are designed to enhance performance and extend tool life. These thread mills are equipped with coolant channels that promote effective coolant flow, ensuring the cutting edges stay cool and reducing the risk of heat-related issues. By maintaining optimal tool hardness during the cutting process, Scientific Cutting Tools’ coolant-through thread mills provide long-lasting performance and reliability.

The coolant-through technology in these thread mills plays a vital role in improving productivity and achieving high-quality threads. By keeping the tool cool, it helps prevent excessive wear and ensures consistent and accurate cutting results. This technology also supports the effective evacuation of chips, further enhancing performance and efficiency.

| Coolant-Through Thread Mills | Features |

|---|---|

| Enhanced tool life | Allows for prolonged usage and reduced downtime |

| Efficient coolant flow | Promotes effective heat dissipation and chip evacuation |

| Consistent thread quality | Ensures accurate and precise thread cutting |

The use of coolant-through thread mills from Scientific Cutting Tools not only improves overall tool performance but also contributes to extended tool life. Their innovative design and functionality make them an excellent choice for various machining applications ranging from aerospace to medical to job shops. With Scientific Cutting Tools’ coolant-through thread mills, users can achieve exceptional results, reduce tool wear, and optimize productivity.

Indexable Boring Bars, Port Tools, and Thread Mills

When it comes to machining processes, having the right tools can make all the difference in efficiency and performance. That’s why Scientific Cutting Tools offers a comprehensive line of indexable boring bars, port tools, and thread mills, all designed to optimize your cutting operations.

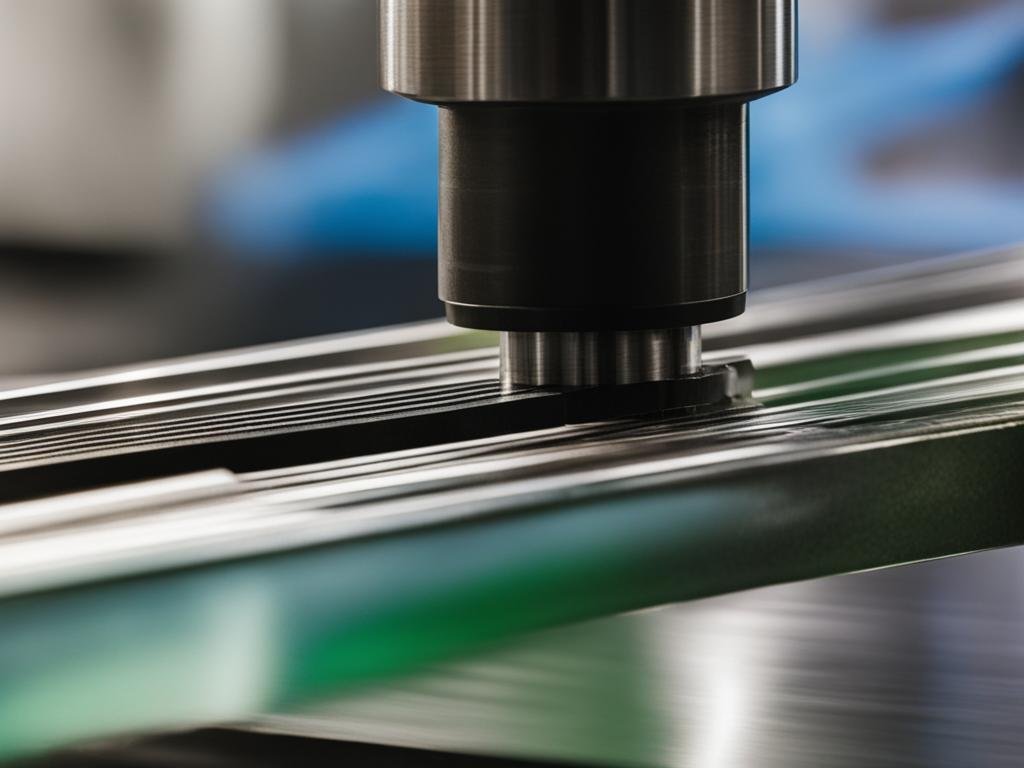

One of the standout features of these cutting tools is the utilization of through-coolant technology. Through-coolant technology allows for improved chip evacuation and reduced heat build-up during machining, ultimately resulting in better tool life and superior cutting performance.

With optimal coolant flow, these indexable boring bars, port tools, and thread mills from Scientific Cutting Tools ensure efficient and reliable cutting operations. Whether you’re working with challenging materials or tackling complex geometries, the use of through-coolant technology guarantees consistent and precise results.

Why Choose Indexable Boring Bars, Port Tools, and Thread Mills?

Through-coolant technology offers several advantages that make indexable boring bars, port tools, and thread mills a preferred choice for many machinists:

- Improved chip evacuation: Through-coolant channels facilitate efficient chip evacuation, reducing the risk of chip clogging and improving overall machining productivity.

- Reduced heat build-up: By allowing for optimal coolant flow, heat build-up is minimized, resulting in longer tool life and reduced tool wear.

- Enhanced cutting performance: The combination of through-coolant technology and precision tool design ensures superior cutting performance, even in challenging machining applications.

The image above demonstrates the importance of through-coolant technology in maintaining optimal coolant flow during cutting operations, contributing to improved chip evacuation and reduced heat build-up.

| Product | Features |

|---|---|

| Indexable Boring Bars | Designed for precision boring operations Various sizes and configurations available |

| Port Tools | Ideal for creating precision ports in various materials Optimized design for efficient chip evacuation |

| Thread Mills | Allows for accurate thread milling Available in multiple thread sizes and configurations |

With a range of products to choose from, including indexable boring bars, port tools, and thread mills, Scientific Cutting Tools has you covered for all your machining needs. Their commitment to innovation and precision ensures that you can trust their cutting tools to deliver exceptional results consistently.

Upgrade your cutting operations with indexable boring bars, port tools, and thread mills that utilize through-coolant technology, and experience the efficiency and performance benefits firsthand.

Cutting Tools Catalog

Scientific Cutting Tools offers a wide range of cutting tools in their comprehensive catalog. This catalog showcases their solid carbide and carbide-tipped cutting tools that are widely used in industries such as aerospace, medical, defense, and job shops. Each tool is crafted with precision and durability in mind, ensuring exceptional performance and reliable results.

From Acme and stub Acme thread mills to specialty end mills and boring bars, the catalog covers a diverse range of cutting solutions to meet various application needs. Whether you’re working with tough materials in aerospace and defense or require precision machining for medical and job shop applications, Scientific Cutting Tools has the right tool for the job.

With their solid carbide and carbide-tipped cutting tools, Scientific Cutting Tools provides the strength and durability needed to achieve optimal results. These cutting tools are manufactured with high-quality materials and advanced technology to withstand the demands of even the most challenging projects.

Take a look at a sample selection of cutting tools available in the catalog:

| Tool | Description |

|---|---|

| Acme and stub Acme thread mills | Designed for efficient and precise threading in various materials, including tough alloys and steels. |

| Specialty end mills | Provides superior performance in specific applications such as profiling, slotting, and contouring. |

| Boring bars | Offers reliable and accurate hole boring operations for a wide range of job shop applications. |

Scientific Cutting Tools’ cutting tools catalog is a valuable resource for professionals in the aerospace, medical, defense, and job shop industries looking for high-performance tools that deliver consistent and precise results.

Acme and Stub Acme Lathe Threading Tools

Scientific Cutting Tools specializes in providing Acme and stub Acme lathe threading tools that are made from solid carbide.

These high-quality cutting tools are specifically designed to tackle demanding applications in tough materials, offering exceptional performance and durability. With their precision manufacturing and solid carbide construction, Scientific Cutting Tools’ Acme and stub Acme lathe threading tools ensure accurate and reliable thread cutting on a wide range of materials.

Whether you’re working with tough metals, alloys, or other challenging materials, these threading tools are engineered to deliver superior results.

Upgrade your machining capabilities with Scientific Cutting Tools’ Acme and stub Acme lathe threading tools, designed to meet the high demands of tough materials while maintaining precision and performance.

PCD-Tipped and CBN-Tipped Boring Bars

In challenging machining applications that involve abrasive nonferrous materials such as silicon, aluminum, ceramics, and composites, Scientific Cutting Tools offers a range of PCD-tipped boring bars. These bars are specifically designed to withstand the demands of these materials, providing optimal performance and durability. With their PCD (polycrystalline diamond) tips, these boring bars offer superior hardness and wear resistance, resulting in longer tool life and excellent cutting performance.

For machining tough and abrasive ferrous metals measuring 45 HRc or harder, Scientific Cutting Tools provides CBN-tipped boring bars. The CBN (cubic boron nitride) tips on these bars are engineered to deliver exceptional results in machining these challenging materials. With their superior hardness and thermal stability, CBN-tipped boring bars ensure efficient material removal and reduce the risk of tool wear, resulting in improved productivity and cost-effectiveness.

Scientific Cutting Tools offers a complete line of PCD-tipped and CBN-tipped boring bars, catering to a wide range of materials and applications. Whether you need to tackle abrasive nonferrous materials or ferrous metals, their cutting solutions provide the durability and performance required to achieve precise and efficient machining operations.

| Type of Boring Bar | Applications |

|---|---|

| PCD-Tipped Boring Bars | Abrasive nonferrous materials such as silicon, aluminum, ceramics, and composites |

| CBN-Tipped Boring Bars | Ferrous metals measuring 45 HRc or harder |

Thread Milling Cutters

Scientific Cutting Tools specializes in manufacturing Acme and stub Acme thread milling cutters. These cutters are designed to deliver precise and accurate thread milling results in a wide range of applications. Available in various thread sizes, ranging from 1/4″-16 to 1″ – 5″, these thread milling cutters offer versatility and performance. Whether you need Acme thread milling cutters or stub Acme thread milling cutters, Scientific Cutting Tools has you covered.

For internal threading, Scientific Cutting Tools offers internal UN thread mills and internal metric thread mills. These thread mills are perfect for creating internal threads of different sizes and specifications accurately. With their high-quality construction and precision design, these thread mills ensure optimal performance and reliability.

If you require external threading, Scientific Cutting Tools also provides external thread mills. These mills are designed to create external threads with precise dimensions and quality finishes. The external thread mills make it easy to produce threaded parts for a variety of applications.

When it comes to thread milling cutters, Scientific Cutting Tools is committed to providing high-quality tools that meet the diverse needs of manufacturers and machinists. Whether you need to mill internal or external threads, Acme or stub Acme, or specific thread sizes, their range of thread milling cutters ensures you have the right tool for the job.

Advantages of Scientific Cutting Tools Thread Milling Cutters:

- Precise and accurate thread milling results

- Wide range of thread sizes available

- Internal UN and metric thread mills for accurate internal threading

- External thread mills for precise external threading

- High-quality construction for long-lasting performance

| Thread Milling Cutter Type | Thread Sizes |

|---|---|

| Acme Thread Milling Cutters | 1/4″-16 to 1″ – 5″ |

| Stub Acme Thread Milling Cutters | 1/4″-16 to 1″ – 5″ |

| Internal UN Thread Mills | Various thread sizes |

| Internal Metric Thread Mills | Various thread sizes |

| External Thread Mills | Various thread sizes |

Choose the thread milling cutter that suits your specific threading needs and experience precision and reliability with Scientific Cutting Tools.

Online Catalog and Tool Locator

Scientific Cutting Tools offers an extensive online catalog that showcases their most popular cutting tools and sizes. This user-friendly online resource allows customers to easily browse and select the tools they need for their applications.

The online catalog provides direct links to the specific items in Scientific Cutting Tools’ online store, making it convenient for customers to find and purchase the tools they require. With just a few clicks, users can explore a wide range of cutting tools, including boring bars, threading tools, groove tools, and porting tools.

Customers can search for specific tools using part numbers or simply browse through the various categories to discover the perfect cutting solution. The online catalog also highlights the most popular cutting tools, ensuring that customers have access to the tools that are in high demand.

Whether you’re searching for precision end mills, durable inserts, or high-performance toolholders, the online catalog from Scientific Cutting Tools provides a comprehensive resource for finding the right cutting tools for your specific needs.

Take advantage of the convenience and efficiency of the online catalog and tool locator to streamline your tool selection and purchase experience. Scientific Cutting Tools’ online store is a one-stop destination for all your cutting tool needs.

| Category | Description |

|---|---|

| Boring Bars | High-quality cutting tools designed for precision bore machining operations. |

| Threading Tools | Cutting tools used for creating internal and external threads with accuracy and efficiency. |

| Groove Tools | Tools for machining grooves, often used in applications requiring close tolerances and smooth finishes. |

| Porting Tools | Specialized tools for machining ports, providing precise and reliable results. |

Conclusion

Scientific Cutting Tools is a renowned manufacturer of high-quality cutting tools that are widely recognized for their precision, performance, and reliability. With an extensive range of innovative cutting solutions, including coolant-through technology and indexable tooling sets, they cater to diverse industries with exceptional precision and efficiency. Scientific Cutting Tools’ unwavering commitment to manufacturing excellence and customer satisfaction has established them as a trusted partner for cutting-edge solutions.

Whether it’s the aerospace, medical, defense, or job shop sectors, Scientific Cutting Tools’ products consistently deliver outstanding results. Their commitment to incorporating advanced technology and employing superior craftsmanship ensures that their cutting tools consistently meet the highest standards of quality and performance. Customers can rely on Scientific Cutting Tools to provide them with cutting-edge tools that enhance both productivity and precision.

For those seeking cutting solutions that combine innovation, precision, and reliability, look no further than Scientific Cutting Tools. Contact them today to explore their extensive range of manufacturing tools and experience firsthand the exceptional performance and productivity their products bring to any application.

FAQ

Q: What are the product categories offered by SCT USA?

A: SCT USA offers an array of standard and custom cutting tools, including drill, groove, and system tools.

Q: Where can I find videos showcasing the products of SCT USA?

A: You can find videos showcasing the products of SCT USA on their website www.sct-usa.com.

Q: How can I contact SCT USA to inquire about their cutting tools and accessories?

A: You can contact SCT USA by clicking on the “Contact” section on their website and filling out the inquiry form.

Q: Does SCT USA offer custom cutting tools?

A: Yes, SCT USA offers custom cutting tools made from the finest compressed sub-micron carbide to meet specific requirements.

Q: What are the features of SCT USA’s cutting tools?

A: SCT USA’s cutting tools are made from the finest compressed sub-micron carbide and are available in both standard and custom options to suit different machining needs.

Q: Does SCT USA offer single point cavity tools?

A: Yes, SCT USA offers single point cavity tools in various options like length, diameter, and flute to fulfill different cutting requirements.

Q: How can I order cutting tools from SCT USA?

A: You can place an order for cutting tools by contacting their sales department through the “Contact” section on their website.

Q: Does SCT USA offer uncoated cutting tools?

A: Yes, SCT USA offers uncoated cutting tools that are highly efficient and perform exceptionally well in various machining operations.

Q: Are there any modification options available for the cutting tools offered by SCT USA?

A: Yes, SCT USA provides modification options for their cutting tools to meet specific machining requirements and applications.

Q: What are the advantages of using SCT USA’s cutting tools?

A: SCT USA’s cutting tools are manufactured using the finest compressed sub-micron carbide, ensuring high quality, precision, and durability for efficient machining results.